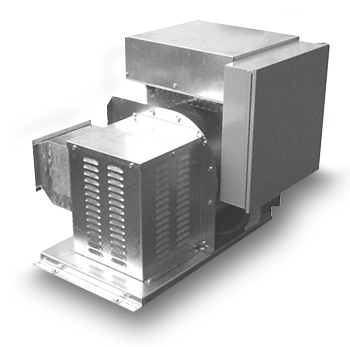

Gas Hot Air Blowers

HIGH & LOW PROFILE GAS HOT AIR BLOWERS

High Profile Models 950, 953, and 955

- 2, 3, and 5 hp direct-drive motor

- 400,000, 600,000, and 900,000 Btu bungalows

- 60 KW, 2HP, 480 VAC

- Propane or natural gas powered

- Efficient two-stage design with built-in energy management

- Adjustable air temperature control

- Built-in snow detector control

- Complete flame safety control system

- Adjustable run timer

- Conserves resources

- Dry contact or 24 VDC indication circuit

- High-efficiency air foil-type blower

- Adjustable mounting foundations

- Programmed for on-demand use

- Advance controls allow for customization of operating parameters to reduce operating expense

- Remote control operation via dispatch or Rail-NET™

- Quick Change nozzle kits

- Remote monitoring software allows convenient real-time access to the status of equipment and data

- Allows viewing of historical data and uses information to help determine future and occurring maintenance issues Beneficial for preventative maintenance

- Monitors live data points; customer based

- Status page shows current status of faults, fault count readings, and settings

- Remotely edit configuration of equipment

Low Profile Models 951, 952, and 954

- 2, 3, and 5 hp direct-drive motor

- 400,000, 600,000, 900,000 Btu bungalows

- Propane or natural gas powered

- Efficient two-stage design with built-in energy management

- Adjustable air temperature control

- Built-in snow detector control

- Complete flame safety control system

- Adjustable run timer

- Conserves resources

- Dry contact or 24 VDC indication circuit

- High-efficiency air foil-type blower

- Adjustable mounting foundations

- Programmed for on-demand use

- Advance controls allow for customization of operating parameters to reduce operating expense

- Remote control operation via dispatch or Rail-NET™

- Quick Change nozzle kits

Rail-NET Remote Monitoring Capabilities

- Remote monitoring software allows convenient real-time access to the status of equipment and data

- Allows viewing of historical data and uses information to help determine future and occurring maintenance issues

- Beneficial for preventative maintenance

- Monitors live data points; customer based

- Status page shows current status of faults, fault count readings and settings

- Remotely edit configuration of equipment